While 83% of commercial refrigeration decisions are based on initial cost alone, this approach often leads to substantial financial losses over time. When selecting between custom and standard commercial refrigerators, you must ponder factors above the price tag. From energy consumption patterns to inventory optimization capabilities, each option presents distinct advantages that can drastically impact your business’s bottom line. Understanding these critical differences will shape your operational success in the years ahead.

Understanding Custom and Standard Commercial Refrigerators

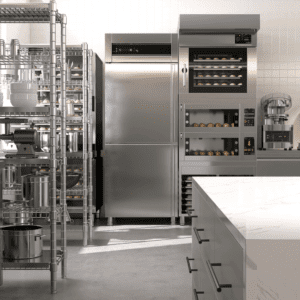

Understanding the fundamental differences between custom and standard units will significantly impact your business operations when evaluating commercial refrigeration options. Custom refrigerators are engineered to meet your specific requirements, offering precise temperature control and storage configurations that align with regulatory compliance and food safety standards.

Standard commercial refrigerators provide a more economical solution with proven designs and readily available parts. While they’re built for general commercial use, they may not optimize your space or deliver the exact performance parameters your operation demands. Custom units often feature superior components and energy efficiency, though they require a higher initial investment.

The decision finally hinges on your operational needs, available space, and budget constraints. Consider how each option aligns with your long-term business goals and specific industry requirements.

Key Differences in Design and Manufacturing

Custom and standard commercial refrigerators’ design and manufacturing processes reveal distinct methodologies that shape their final performance. When evaluating component quality, custom units incorporate premium materials and precision-engineered parts, resulting in superior durability and operational efficiency.

Manufacturing complexity varies considerably between the two options. Custom refrigerators require intensive collaboration between manufacturers and clients, involving detailed specifications and specialized production techniques. Standard models, however, rely on streamlined mass production methods that reduce costs but limit customization options.

You’ll notice this difference in the final product. Custom units like walk-in refrigerators offer tailored solutions for specific commercial needs, while standard models provide reliable but generic functionality. The manufacturing approach directly impacts the unit’s performance and integration capabilities within your commercial space.

Performance and Cooling Efficiency Comparison

Performance differences between custom and standard commercial refrigerators become evident through their cooling capabilities and energy consumption patterns. Custom units typically achieve superior temperature accuracy due to their larger-capacity evaporator coils and specialized compressor systems. These components work together to maintain ideal cooling consistency throughout the storage space.

While standard models offer reliable performance for general commercial use, custom refrigerators excel in situations requiring precise temperature control and enhanced energy efficiency. Fan-assisted cooling systems in custom units provide more uniform air distribution, reducing hot spots and temperature fluctuations. Your energy costs may decrease with a custom unit’s improved cooling efficiency, though you’ll need to maintain both types regularly by cleaning coils and checking seals to guarantee peak performance.

Cost Analysis: Initial Investment vs. Long-Term Value

Investing in a commercial refrigerator requires careful consideration of both immediate costs and long-term financial implications. While custom units have higher upfront costs, their enhanced energy efficiency and durability often translate into significant savings over time.

When calculating total life cycle costs, you must factor in energy consumption, maintenance requirements, and potential replacement timelines. Custom refrigerators typically offer better return on investment through reduced utility bills and lower maintenance expenses. Their specialized features, like optimized storage configurations, can help minimize food waste and improve inventory management.

Although less expensive, standard models may require more frequent repairs and upgrades as your business evolves. To make an informed decision, you’ll want to evaluate your budget constraints against long-term operational savings and efficiency gains.

Installation Requirements and Space Considerations

Before proceeding with any commercial refrigeration installation, you must carefully evaluate your available space and technical requirements. Custom units demand specialized installation procedures and precise measurements to guarantee excellent performance, while standard models offer greater flexibility in placement and setup.

Standard refrigerators may prove more practical when dealing with spatial constraints, as they’re designed to fit conventional kitchen layouts. Custom units require extensive planning, including coordinating with various contractors and confirming proper ventilation and maintenance access clearances. During the planning phase, you must factor in doorway dimensions, ceiling heights, and utility connections.

Consider how your chosen unit will integrate with existing equipment and workflow patterns. Standard models typically require less modification to your space, while custom installations may necessitate structural changes or additional mechanical considerations.

Maintenance and Service Accessibility

While both custom and standard commercial refrigerators require ongoing maintenance, their service accessibility features can differ considerably. Standard models typically follow established servicing protocols, with easily replaceable parts and standardized maintenance procedures. Custom units may require specialized knowledge and specific maintenance routines tailored to their unique configurations.

Component accessibility varies between the two options. Standard models often feature universal design elements that simplify routine tasks like coil cleaning and filter replacement. Custom units can be designed with enhanced access panels and strategic component placement, though their specialized nature might require authorized technician servicing. You’ll want to implement a thorough maintenance program regardless of your choice, as regular upkeep by qualified professionals will maximize efficiency, prevent costly breakdowns, and extend your refrigerator’s operational lifespan.

Customization Options and Design Flexibility

How you customize your commercial refrigeration system can greatly impact your business operations and customer experience. Custom units give you complete control over climate control features, allowing you to maintain precise temperatures for different product zones. You can specify shelving configurations that maximize storage capacity while ensuring ideal product visibility.

Your customization choices extend beyond functionality to aesthetic elements. You can select from various stainless steel finishes, glass door designs, and lighting configurations that align with your brand image. Advanced security features like programmable door locks and temperature monitoring systems protect your inventory investment.

While standard units offer basic flexibility, custom refrigeration solutions enable you to create a system that perfectly matches your operational workflow, space constraints, and product display requirements.

Energy Consumption and Operating Expenses

Understanding energy consumption patterns is critical to effectively managing commercial refrigeration costs. When evaluating custom versus standard units, custom-built models often incorporate advanced energy-efficient features that can drastically reduce utility rates and carbon footprint.

Custom refrigerators typically offer superior insulation systems and high-efficiency compressors that minimize energy waste. You’ll benefit from sophisticated controls that optimize cooling cycles based on usage patterns. While these features increase the initial investment, they’ll generate substantial long-term savings on operating expenses.

To maximize efficiency with either option, you must maintain clean condenser coils, guarantee proper door seals, and minimize door openings. Combined with the right equipment choice, these practices will help you achieve ideal energy performance and cost management in your commercial refrigeration system.

Industry-Specific Applications and Benefits

The versatility of custom commercial refrigeration systems provides distinct advantages across diverse industry sectors. Industry-specific configurations equipped with advanced control systems and temperature monitoring capabilities deliver exemplary performance for your unique requirements.

- Restaurants maximize kitchen workflow with specialized compartments for different ingredients.

- Grocery stores benefit from customized display cases that enhance product visibility while maintaining exact temperature zones.

- Hotels integrate refrigeration seamlessly into their design aesthetic while meeting varied storage needs.

- Healthcare facilities rely on precise temperature control for sensitive materials and compliance requirements.

- Food manufacturing plants optimize production efficiency with tailored cooling solutions.

Making the Right Choice for Your Business Needs

Selecting the right commercial refrigeration system is a crucial decision that impacts your business’s efficiency, cost savings, and regulatory compliance. Custom units provide superior durability, energy efficiency, and tailored solutions for specialized needs, making them a valuable long-term investment. On the other hand, standard models offer affordability and ease of installation, which may suit businesses with more general requirements.

At All Southern Fabricators, we understand that every business has unique refrigeration needs. Whether you require a custom-engineered solution or a high-quality standard model, our team is here to guide you in making the best choice for your operation. Contact us today to discuss your refrigeration requirements and discover how our expertise can enhance your business’s performance.